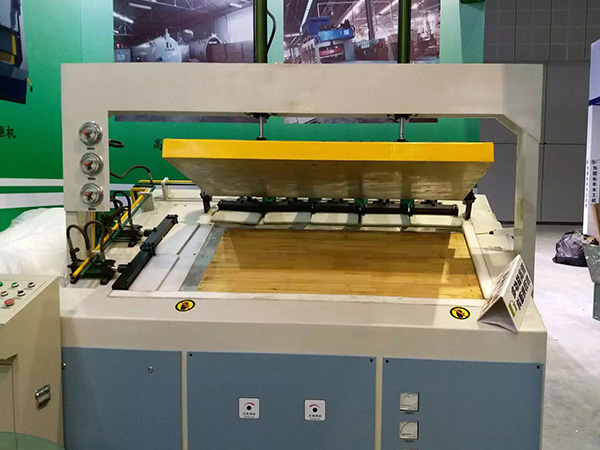

Small Type HF Board Jointing Machine With Slope Workbench

Release Time:2021-08-30

The electrical components are all imported or domestic top accessories, such as Omron, Siemens, Eaton, etc. All of the hydraulic components are Taiwan's original. It adopts PLC and touch screen, simplifying the control process and operation. The program design is diverse and widely used.

Small high frequency board jointing machine with slope workbench can joint plate, solid wood doors and assembly window’s frame assembly (quadrilateral edge, door core splicing), wood edge, L-type sets of lines. It is widely used in the doors, cabinet doors, furniture and other industries.

Features

1. The machine uses tilting table. It is easy to pick and put the workpiece and can save labor.

2. This machine is equipped with automatic alarm systems and safety devices to prevent the danger caused by improper operation.

3. It is PLC and touch screen control system. Simple and easy to understand.

4. It uses three-dimensional pressure, which can ensure the average force. The sheet produced will be flatness and the wooden frame will be with high precision. It is the first choice for the wood industry.

5. Multiple protection and alarm system will make it more scientific and more humane.

The electrical components are all imported or domestic top accessories, such as Omron, Siemens, Eaton, etc. All of the hydraulic components are Taiwan's original. It adopts PLC and touch screen, simplifying the control process and operation. The program design is diverse and widely used.

Diverse programming for a wide range.

Basic parameter

| Model | GXPZ-600-DT |

| Lateral pressure | Cylinder diameter50 hydro-cylinder4(5) |

| Upper pressure | Cylinder diameter50 hydro-cylinder2 |

| Max working size | 600*1200(800*1600) |

| Splicing thickness | 8-60mm |

| HF output power | 15KW |

| HF generator | Inside |

| Feeding cart | Auto |

| Control mode | PLC touch screen |

| Component | Omron, Eaton, Siemens |

| Weight | 2.5T |

haode5858@126.com

haode5858@126.com 0311-83506165

0311-83506165

冀公网安备 13012302000304 号

冀公网安备 13012302000304 号